In domestic ventilation systems — particularly MVHR (Mechanical Ventilation with Heat Recovery) — the correct choice of duct size is critical to achieving airflow targets, system efficiency, and system noise - the last one being the thing that most of us are concerned about! If you have a design for your home MVHR system and it's proposing the use of 75mm ducting, it might be time to consider if this will be the best system for optimal performance in your home.

For raidal systems, using semi-rigid ducting, both 75mm and 90mm ducting is available. This gives some flexibility for different applications and the space available to install the ductwork, however careful consideration should be given to the impact it will have on the end result - the installed performance.

Whilst that 15mm might not seem much, it will affect performance.

We advise the MVHR Unit is sized correctly to avoid having to run it at higher rates, causing high levels of noise and potentially reducing the lifespace of the unit - the same goes for the ducting. It all works together to deliver the end performance. Quite simply- a unit required to deliver a high airflow level doesn't need to be choked by small diameter ducting.

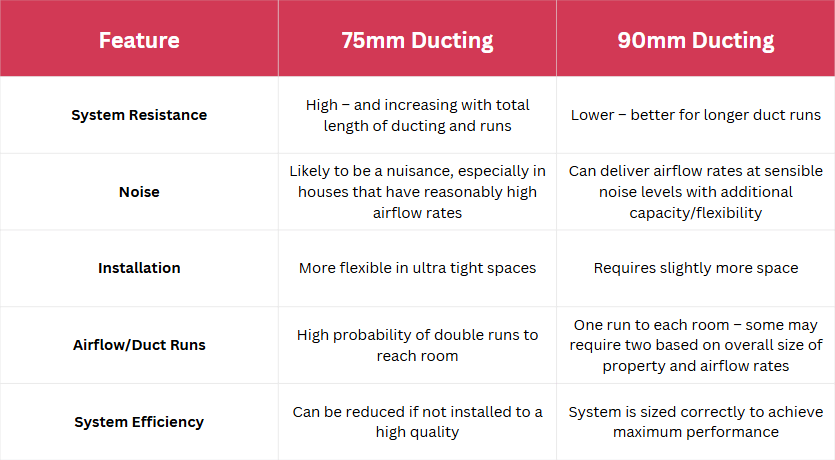

Lets look at the key differences between 75mm and 90mm ducting in terms of:

• Airflow and system resistance

• Noise

• Installation considerations

• Other practical implications

Internal Area and Airflow Capacity

Impact: The 90mm duct has around 40-60% more internal area than a 75mm duct, allowing it to carry more air with less resistance.

Pressure Loss and System Resistance

The internal resistance of ducting has a significant impact on fan performance and system efficiency.

Impact: A longer run of 75mm ducting will result in significantly higher system pressure compared to 90mm ducting. Over 10m, this could mean a difference of 20–30 Pa, which increases fan workload, energy usage, and noise.

Noise Considerations

Noise in a ventilation system is a nusiance!

Noise can be linked to a fan unit, turbulent airflow, and excessive pressure within the system. The aim is to design the system to run a MVHR system no more than 50% for trickle speed and 75% for boost - if the unit is sized properly, the ducting must match.

If you consider how much air has to be moved - out of the large duct ports on top of the unit, and then down to a small 75mm round tube, it is not suprising that it will cause additional and unncessary noise.

Undersized ducting can cause:

• Air velocity/pressure increases, leading to turbulence

• Whistling or whooshing noises at air valves

• Higher breakout noise

Impact:

At 25 L/s airflow:

• 75mm duct: ~7.1 m/s (can exceed 8 m/s at 30 L/s)

• 90mm duct: ~4.8 m/s

(m/s metres per second)

Air velocities over 5 m/s can begin to cause perceptible noise, especially in quiet residential settings.

At 30 l/s, 75mm ducts often exceed acceptable acoustic thresholds without mitigation including acoustic sliences, which can increase the cost of the project - often more cost effective to switch up to the larger duct size.

Other Considerations

A. Space and Flexibility

• 75mm: Easier to route in tight ceiling voids and joist spaces.

• 90mm: Requires slightly more space but fewer runs needed for same airflow e.g. 75mm may need double runs to some rooms to achieve the correct airflow, again, diluting any potential cost savings

B. Balancing and Commissioning

• Systems using 75mm ducting are more sensitive to installation variances. Any issues would have further impact on resistance.

Recommendations

• Use 90mm ducting where possible, especially for longer runs (>8m) or higher airflow requirements

• 75mm ducting may still be appropriate for small rooms where space is constrained — but noise and balancing must be carefully managed.

• Follow manufacturer specific performance data and use system design software or engineers to ensure compliance with airflow and acoustic standards.

Share

Share

Back to Blog